Adverts

A 3D printing technology has revolutionized several sectors, from industrial manufacturing to medicine. A innovation in 3D printing has enabled significant advances, making it possible to create complex products with precision and speed, in addition to paving the way for the bioprinting of human organs.

3D printing, also known as additive manufacturing, uses techniques that build three-dimensional objects from digital files. By superimposing successive layers of materials, this technology makes it possible to create intricate and customized objects, which were previously unfeasible with traditional manufacturing methods.

Adverts

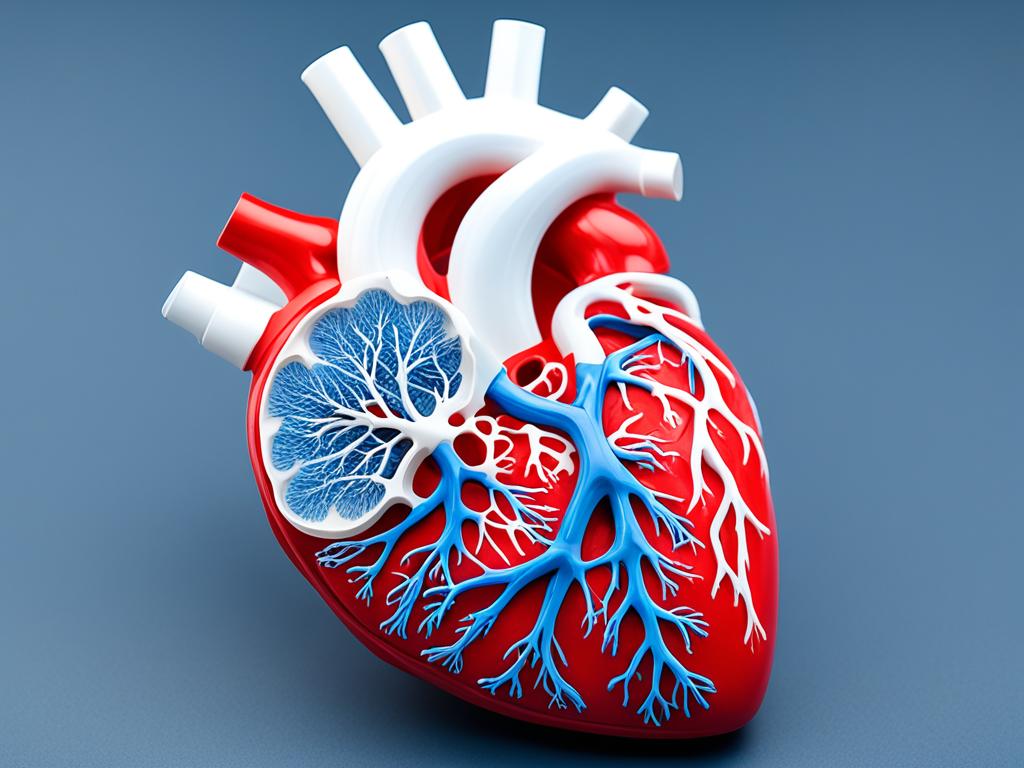

Nowadays, 3D printing goes far beyond rapid prototyping. With advances in the materials used, it is possible to print functional and durable parts for various industrial applications. Furthermore, medicine has benefited enormously from this technology, with the ability to print human tissues and organs for transplants and research.

The 3D Printing Revolution is well underway, with continuous advances in technology and new applications being discovered every day. The possibility of creating complex bespoke objects and manufacturing human tissues and organs are just the beginning. In the coming years, we can expect even more innovations and significant impacts in industry and medicine.

Adverts

Benefits of 3D Printing and Applications in Different Industries

3D printing has revolutionized several industrial sectors, bringing with it a series of significant benefits. This innovative technology has the potential to transform the way we produce and consume, offering advantages ranging from cost reduction to product personalization.

One of the main benefits of 3D printing is the ability to reduce production costs. By eliminating the need for complex tools and traditional manufacturing processes, this technology makes production more efficient and cost-effective. Furthermore, 3D printing allows the use of more accessible materials and the reduction of wasted resources, contributing to sustainability.

Another advantage of 3D printing is increased efficiency. With this technology, it is possible to produce complex and intricate parts quickly and precisely. This makes it possible to create prototypes more quickly, accelerating the new product development process and reducing time to market.

Customization is another important benefit of 3D printing. This technology allows for the on-demand production of customized products according to individual customer needs and preferences. This makes it possible to manufacture unique and exclusive products, meeting consumers' increasingly high expectations.

The application of 3D printing spans a wide variety of industries. In medicine, this technology has been used to manufacture personalized prosthetics, implants and even human organs. In the automotive sector, 3D printing is used in the production of parts and components, providing greater efficiency and reducing manufacturing costs. In the construction industry, 3D printing has been explored for manufacturing complex structures, speeding up construction processes and reducing material waste.

By offering tangible benefits and diverse practical applications, 3D printing has established itself as a revolutionary technology with the potential to transform the way we produce and consume. With continued advancements and new discoveries, we can expect even more surprising applications to emerge in the future.

The Future of 3D Printing and the Industrial Revolution 4.0

O future of 3D printing promises to further revolutionize the industry, with the continued development of state-of-the-art 3D printers. These advanced technologies are driving the Fourth Industrial Revolution, also known as Industry 4.0, and impacting several sectors.

To the state-of-the-art 3D printers are expanding the capabilities of 3D printing, allowing the creation of increasingly sophisticated and complex objects and products. With faster print speeds, higher resolutions and advanced materials, these printers are opening doors to new design and manufacturing possibilities.

Furthermore, 3D printing is boosting the industrial revolution 4.0, transforming traditional manufacturing. With the ability to produce custom parts and products on demand, 3D printing is reducing production costs, eliminating the need for inventory, and making manufacturing more efficient and agile.

O impact of 3D printing It is notable in sectors such as medicine, architecture, automotive and aerospace. In medicine, for example, 3D printing is revolutionizing the manufacturing of prosthetics, artificial organs and personalized medical devices. In construction, 3D printing is making it possible to create complex structures and even homes in short periods of time. In the automotive industry, 3D printing is being used in rapid prototyping and manufacturing custom parts.